Soil mixing – Efficiency meets sustainability

Our innovative soil mixing methods fulfill the highest requirements for efficiency, environmental compatibility and technical precision. These proprietary developments from Bauer combine the latest mixing technologies with customized adaptability – base carriers as well as tools and equipment can be adjusted flexibly to the requirements of the specific construction task.

Rely on sustainable technologies that not only meet modern standards but also help to actively shape the future world of construction. Discover how our soil mixing methods are setting new standards from an economical, technical and ecological perspective.

Innovative soil mixing methods for efficient foundations and challenging construction tasks

Our custom methods for a wide range of construction soils at a glance

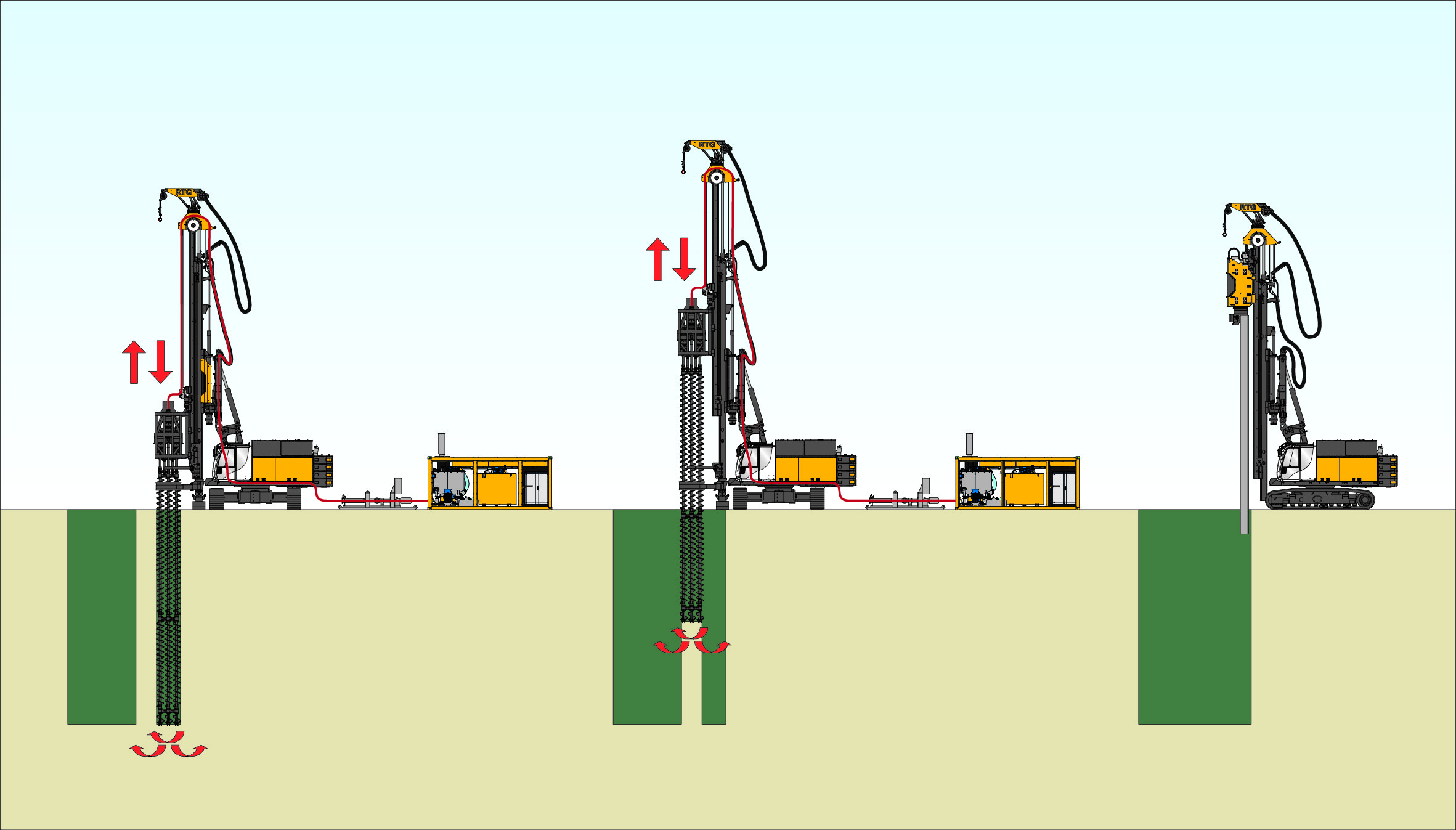

Mixed-in-Place (MIP®)

The Mixed-in-Place method (MIP®) is one of the most established and efficient soil mixing methods in specialist foundation engineering. Thanks to decades of practical experience, this method can be used in nearly all soil types. The counter-rotating triple auger ensures homogeneous mixing of soil strata with the binding agent, directly on site with considerable reductions in excavated soil or material transport.

An overview of the advantages of the MIP® method:

- Sustainable production of construction materials

- High mixing quality with triple auger

- Versatile use for sealing, stabilization, improving load-bearing capacity

- Suitable as cut-off walls and retaining structures for small and large projects

- Considerably reduced removal of materials (resource-efficient)

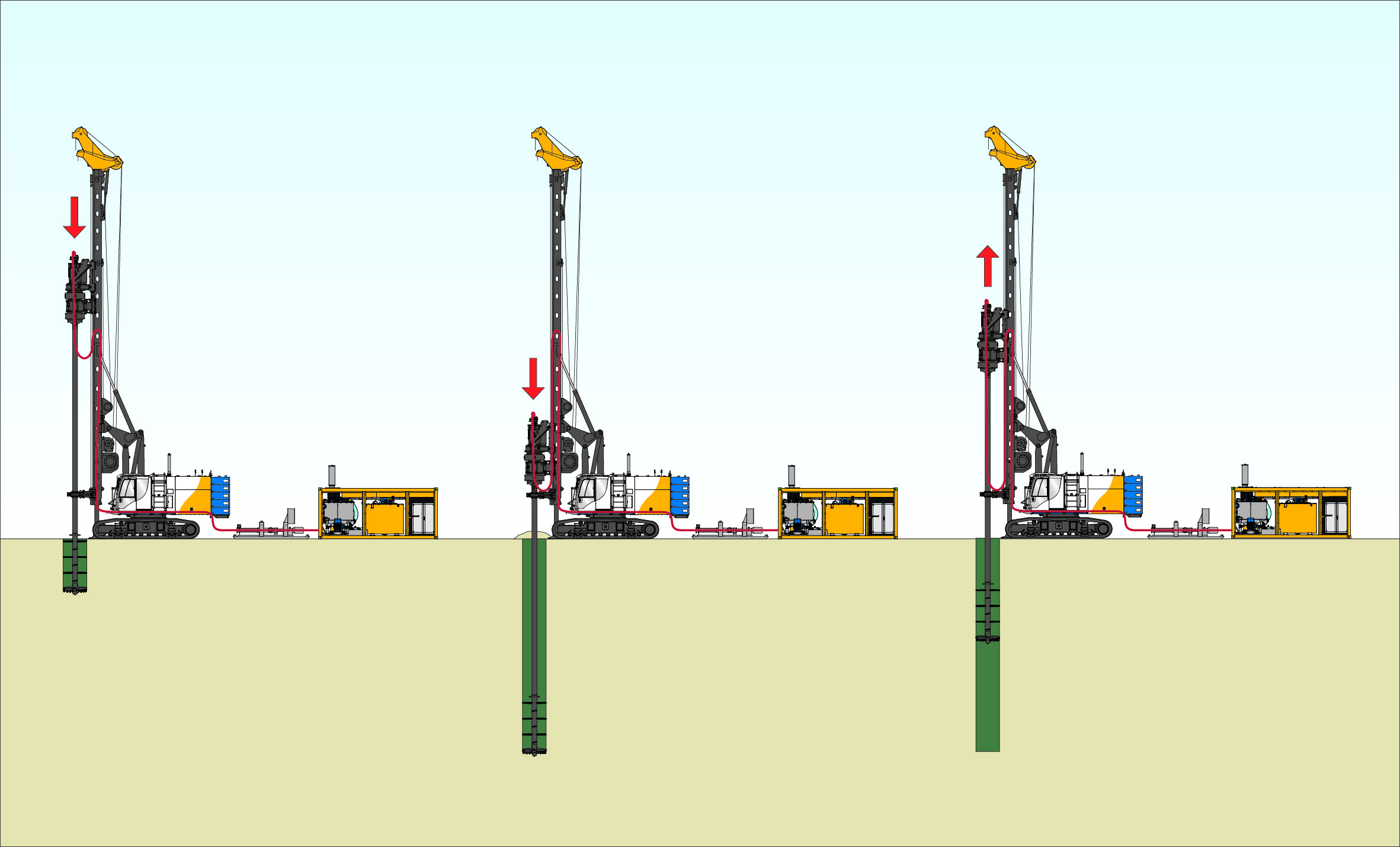

Single-Column-Mixing (SCM)

Single Column Mixing (SCM) is a high-performance, cost-effective soil mixing method for the execution of single columns, walls or blocks. A rotating mixing tool, comprising a starter auger with teeth and/or round shank chisels as well as mixing paddles, thoroughly mixes the soil with a binder slurry on site: fast, precise and low-emission for deep soil stabilization.

An overview of the advantages of the SCM method:

- Rapid construction progress and cost efficiency

- High-precision column installation in the construction soil

- Flexible for custom solutions or large-scale solutions as soil improvement or to prevent soil liquefaction

- Ideal for foundations, transport routes, railway embankments

- Considerably reduced removal of materials (resource-efficient)

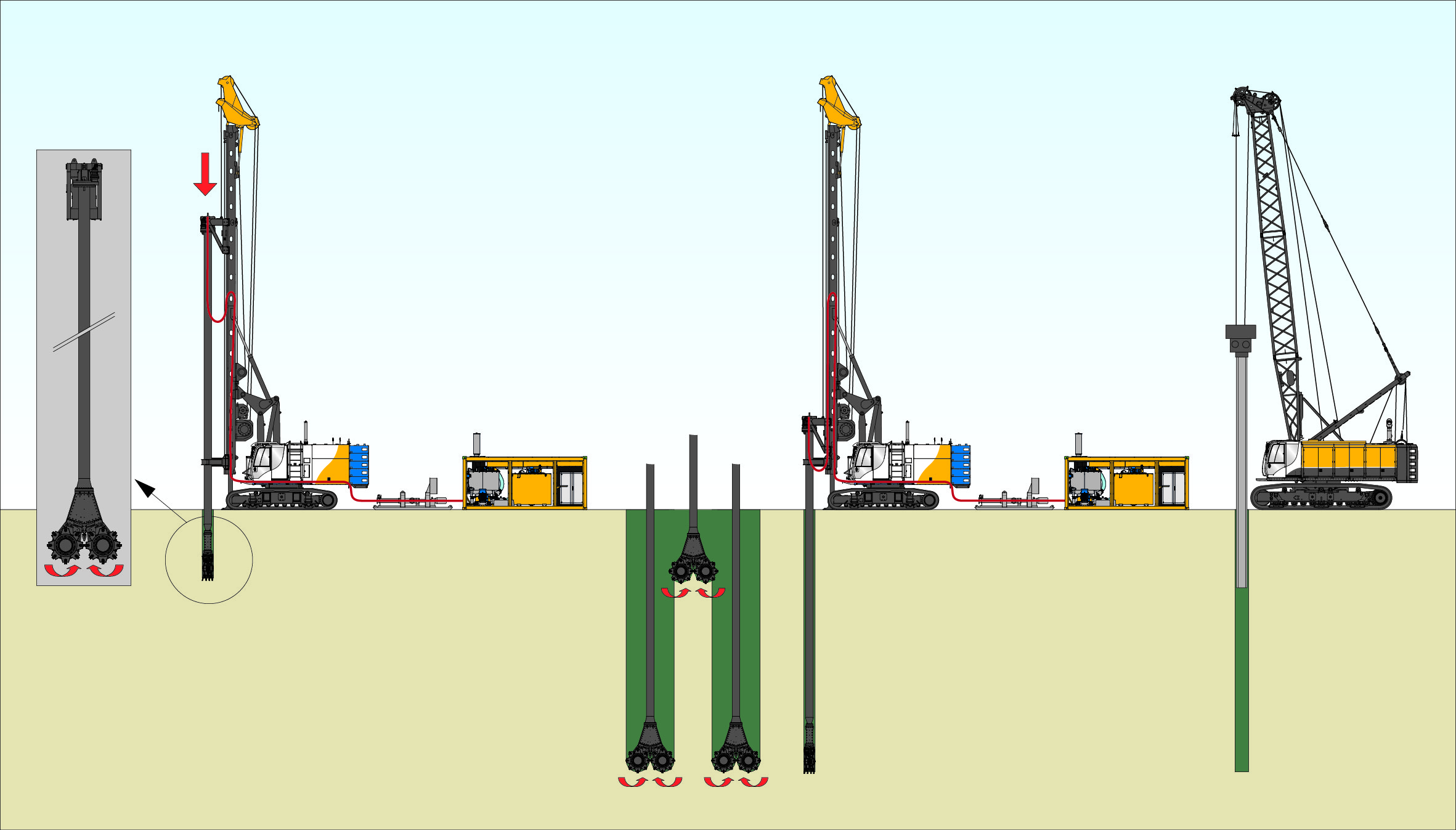

Cutter-Soil-Mixing (CSM)

Cutter Soil Mixing (CSM) is a powerful method for particularly challenging applications in specialist foundation engineering. It combines the advantages of diaphragm wall equipment and soil mixing. Robust cutters are able to safely mix even deep, dense or rocky soils: ideal for dams, dikes and deep excavation pits.

An overview of the advantages of the CSM method:

- Use at great depths even under difficult soil conditions

- High precision for verticality monitoring

- Suitable as cut-off walls and retaining structures

- Socketing possible in harder rock layers

- High settlement and deformation stability

- Considerably reduced removal of materials (Resource-efficient)

FAQ: Frequently asked questions on the topic of soil mixing methods

A soil mixing method is a geotechnical method in which the existing soil is mixed with a binder slurry directly on site (in situ) in order to strategically improve its original characteristics, such as load-bearing capacity, shear strength or water permeability. This method is considered a sustainable solution for specialist foundation engineering, since it achieves considerable reductions in excavated soil and material transport, thereby reducing emissions and construction time.

With soil mixing techniques, a mixing tool – such as an auger, cutter or mixing blade – is inserted into the soil and rotated. At the same time, a binder slurry (for example bentonite or calcium carbonate) is inserted and mixed together homogeneously with the soil. The binding agent-soil mixture hardens and forms load-bearing or sealing elements in the construction soil – directly and without soil loss.

Soil mixing methods are used anywhere the natural construction soil lacks the necessary load-bearing strength or leak tightness. Typical applications include:

In specialist foundation engineering, several soil mixing methods have become established for various construction tasks:

- Mixed-in-Place (MIP®): Homogenization of the soil using a triple auger

- Single Column Mixing (SCM): Column installation using rotating / large-area mixing tool

- Cutter Soil Mixing (CSM): Combination of diaphragm wall and mixing technology for large depths

- This method can be adapted individually to the soil type and project specifications.

Soil mixing methods can be used in a variety of soil types – from soft, cohesive soils to dense sands or even rocky layers (for example using SCM or CSM). Selecting the appropriate method depends on the geology, depth and planned purpose of construction. Modern mixing tools can now accomplish secure, thorough mixing of heterogeneous or cohesive soils.

Soil mixing methods in action!

In order to display the video on the US platform YouTube, we need your consent to the associated data processing, as described in our data protection declaration.

Downloads

Do you have any questions?

Contact our specialists and find the right solution for your construction projects.

Contact Form

You might also be interested in..

Excavation pits, foundations, cut-off walls or soil improvement: Your expert for complex specialist foundation engineering projects. Contact us now and learn more!

Standing still is not an option for us. Because the journey towards a digital, innovative and sustainable future has only just begun. Together into the future.

Discover our wide range of brochures and get a comprehensive insight into our entire portfolio. Browse now!

Here you can find our latest press releases – everything at a glance. Sign up for the press distribution list now and make sure you don’t miss out on any news!